Teamfoto TUM Boring – Las Vegas – Not a boring competition, Image: TUM Boring

Elon Musk’s “Not-a-Boring Competition” took place in Las Vegas. Eight teams of students from around the world competed against each another, drilling with boring machines they had constructed themselves. The TUM team managed to drill 22 meters and won the competition.

Student teams from around the world were called on to drill a tunnel measuring 30 meters in length and one-half meter in diameter with tunnel boring machines (TBM) they have built themselves. 12 of the approximately 400 teams to submit concepts for a tunnel boring machine were selected, including the TUM students. Eight finalists were invited to Las Vegas to compete against one another. After the strict safety briefing, however, only two of the teams were admitted to the actual tunnel boring round to qualify for drilling the 30-meter competition. TUM Boring and Swissloop Tunneling (ETH Zurich). TUM Boring ultimately won the competition boring a 22-meter-long tunnel. In addition to the overall victory, TUM Boring also won in the subcategory for the best navigation system. The “Not-a-Boring Competition” is conducted by “The Boring Company”, a tunnel construction and infrastructure company founded by entrepreneur Elon Musk.

Image: TUM Boring

Innovation in tunneling

Being faster than a snail is truly an innovation in tunneling. TUM Boring – Innovation in Tunneling is an initiative of the Technical University of Munich consisting of 60 highly motivated students who have teamed up to innovate tunneling towards a greener future by developing the fastest and fully functional Tunnel Boring Machine (TBM). Along with their vision TUM Boring won the first Not-a-Boring Competition by Elon Musk’s The Boring Company. The goal was to design and build a Tunnel Boring Machine that tunnels faster than a snail crawls and accelerate the transition to three-dimensional transportation.

TUM Boring’s boring machine weighs a total of 22 tons. It consists of a 12-meter-long shipping container in which components such as the boring head, steel pipes and the propulsion system have been installed. The 60 TUM Boring team members experimented and worked on building their TBM for over a year. The team decided on a method referred to as pipe jacking: During boring, steel pipes are pressed into the ground one after the other and are connected with one another underground.

TUM School of Management students with the trophy. Image: TUM Boring

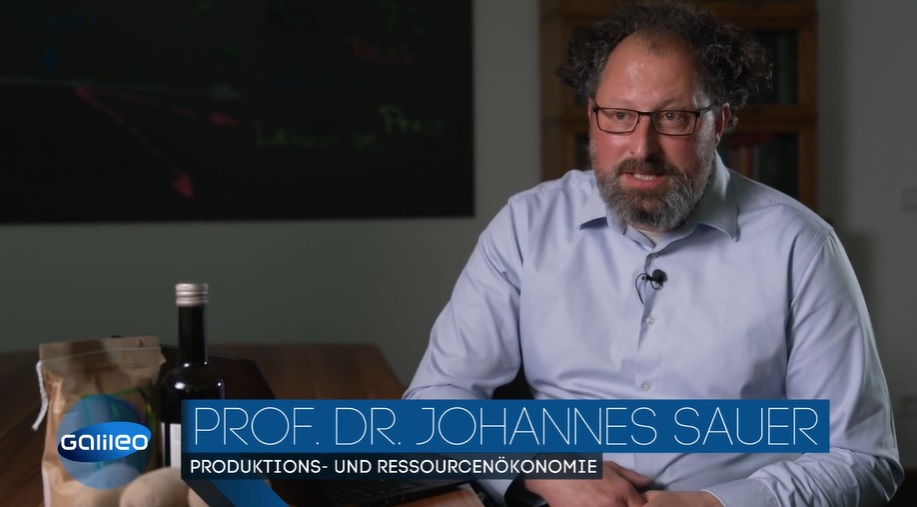

The contribution of TUM School of Management students

Students of the TUM School of Management were an integral part of the TUM Boring team. The TUM SOM team consisted of Louis Jabbour, Irina Butenko, Nathan Bonetti, Moritz Diekhöner, Tolgahan Seren, Felix Güttersberger, Daniel Pflüger, Dmitry Burlakov, Torben Leowald, Katharina Prantl, Max Herbst, Vincent Adler and Marvin von Hagen, all of whom are studying Management & Technology. In an interview, Louis Jabbour and Marvin von Hagen, who are in their 6th Bachelor’s semester, tell us about the challenges and adventures they encountered on their way to victory in Las Vegas.

What aspect of your studies has helped you during TUM Boring?

The most helpful aspect of our studies was the project study, which can be described as a mixture of a bachelor’s thesis and an internship that you do in small teams of typically 3–5 students. While Louis did his in collaboration with EY-Parthenon, Marvin did his in the TUM Hyperloop Team, and the experience from that, especially in terms of structuring such a big student team, was very helpful in setting up TUM Boring.

What were your tasks throughout this whole process of developing the tunneling machine?

Our tasks in the development of the tunnel boring machine were basically everything but the actual development of the tunnel boring machine – instead, we laid the foundation for making this possible. Marvin paused his studies for a whole year to focus completely on TUM Boring as Project Lead on the non-technical side, meaning everything from recruiting to managing tasks and responsibilities. Louis was an important member of TUM Boring’s non-technical team (internally called Operations). His specific responsibilities included coordinating cold calls and emails to over 500 companies, organizing the packaging and shipping of our 22-ton machine to the US, and much more.

What was the biggest challenge during the competition from management perspective?

One of our biggest challenges was the following problem: Without a machine to demonstrate, you don’t get sponsors, and without sponsors, you don’t have the money to build a machine at all. For that reason, we had to work really hard to acquire sponsors. Additionally, many sponsors told us that they had little or no budget for sponsorship due to the COVID-19 pandemic. Although it was way more difficult than expected, we were able to get our first sponsors by the end of 2020. Once we were able to show the first pictures of our actual machine, it became much easier, and we were eventually able to raise enough in-kind and financial support from over 80 companies to successfully build our tunnel boring machine. Many thanks to the Chair for Strategy & Organization, Professor Isabell Welpe, and the Dean of the TUM School of Management, Professor Gunther Friedl, for their excellent support to achieve this!

After the successful victory: What are the next steps for TUM Boring and your future?

The next steps for TUM Boring are to bring our machine back to Germany, fulfill remaining requests from our sponsors such as speeches at company events, etc. How TUM Boring will continue afterward? We don’t know that either! After everything cooled off in the coming weeks, we expect Elon Musk to announce the Rules & Requirements for a second Not-a-Boring Competition. We’re quite certain that, given this year’s success, somebody else will find have the time and dedication needed to bring the victory to Munich for another time. We’ll definitely be there for the second generation by offering advice and support, but we’ll personally be moving on to new pursuits. For Louis, this will be an internship at the TUM-startup FINN, for Marvin it will be the start of his exchange semester at Sciences Po Paris.

The post TUM students win Elon Musk’s “Not-a-Boring Competition” appeared first on Technical University of Munich – School of Management.